The wide range of plastic applications has made its use ubiquitous and at the same time has contributed to the widespread of plastic waste. PL is the 6th largest consumer of plastics in EU. The use of plastics in PL in 2018 is estimated at 3.5M tons (with 9% ann. increase), while in EU the demand equaled 50.7M tons (PlasticsEurope). Every year, Europeans generate over 29 million tons of plastic waste, but less than a third is collected for recycling (32% vs 42% incineration vs 24% landfilling).

The broad range of applications for plastic has resulted in its widespread use and has also contributed to the increase in Plastic Waste.

Poland is the 6th largest consumer of plastics in the EU. The estimated consumption of plastics in Poland in 2018 was 3.5 million tons, while demand in the EU was 50.7 million tons (PlasticsEurope). The use of plastics in PL in 2018 is estimated at 3.5M tons (with 9% ann. increase), while in EU the demand equaled 50.7M tons (PlasticsEurope). Every year, Europeans generate over 29 million tons of plastic waste, but less than a third is collected for recycling (32% vs 42% incineration vs 24% landfilling). Across the world, plastics make up 85% of beach litter.

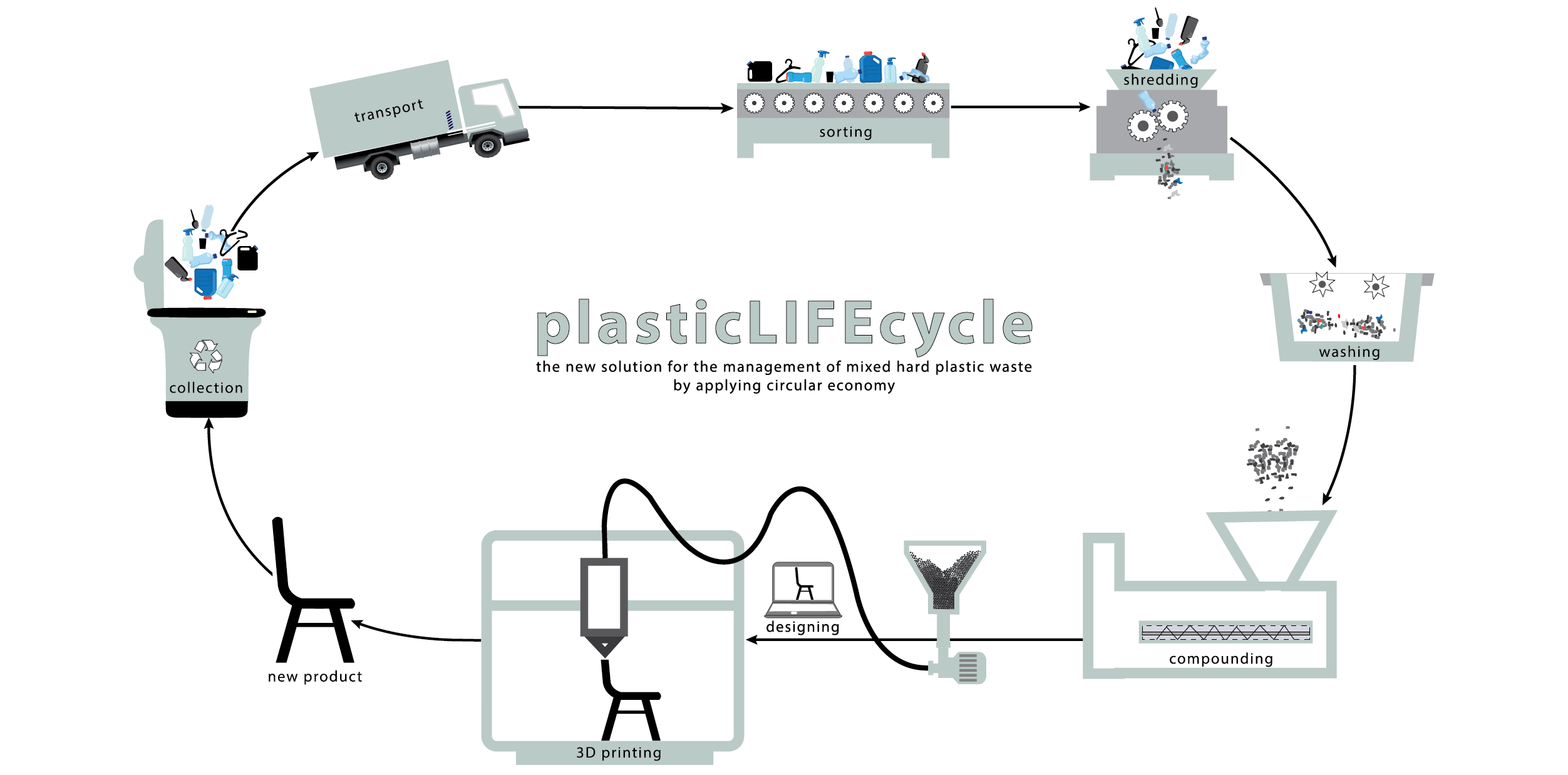

Our solution is a new way of doing business together called the PLC network. It includes everyone in the process of making and using hard plastics and makes sure that everyone benefits. This means that waste disposal places, companies that recycle, and companies that make products from recycled plastic will all work together. This will help to use more recycled plastic materials and reduce waste.

This new business cooperation will only be achievable when the innovative PLC technology is integrated as the heart of the system. The latest recycling solutions are available for only pure/homogeneous plastic fractions (PET, films, etc.). The PLC technology is our innovative solution for sorting heterogeneous hard plastic waste into recyclable fractions and utilizing non-recyclable plastic residue for energy production in the LIFEtec gasification process. The heart of the PLC technology is a 3-PHASE HYDROSTATIC SEPARATOR developed by Investeko SA, guided by the idea of maximizing COST-EFFECTIVENESS both in terms of investment and operation, while ensuring satisfactory performance.

The project aims to demonstrate how to benefit from the potential of a plastic fraction that currently in neither recovered or recycled in a new business concept based on circular economy.

The project is to maximize recycling of mixed hard plastic waste and to increase the uptake of recycled plastics in product manufacturing (contribute to reaching 10Mt of recycled plastics in new products by 2025 as set in the European Strategy for Plastics).

This will be achieved with new business cooperation based on:

![]() to design, implement, test and validate the pilot PLC plant for efficient sorting of mixed hard plastic waste

to design, implement, test and validate the pilot PLC plant for efficient sorting of mixed hard plastic waste

![]() to implement standardized PLC-compatible procedures for mixed hard plastic waste pre-sorting in municipal waste treatment plants and thus to create standardized waste stream as an input to PLCplant (3,500t/y)

to implement standardized PLC-compatible procedures for mixed hard plastic waste pre-sorting in municipal waste treatment plants and thus to create standardized waste stream as an input to PLCplant (3,500t/y)

![]() to design, implement, test and validate the pilot unit for production of tailored compounds for products manufacturing with 70-90% recycled material from PLC (capacity 400t/y)

to design, implement, test and validate the pilot unit for production of tailored compounds for products manufacturing with 70-90% recycled material from PLC (capacity 400t/y)

![]() to design, implement, test and validate the innovative mobile 3Dprinting prototype with 100% recycled material from PLC (capacity 65t/y)

to design, implement, test and validate the innovative mobile 3Dprinting prototype with 100% recycled material from PLC (capacity 65t/y)

![]() to establish new circular business network (i.e. PLCnetwork) to boost cooperation between municipal waste treatment plants, plastic-recyclers and converters (12 plants, 3 countries)

to establish new circular business network (i.e. PLCnetwork) to boost cooperation between municipal waste treatment plants, plastic-recyclers and converters (12 plants, 3 countries)

![]() to increase the quality of recycled polyolefins reaching levels of food packaging production - 3 newly developed tailored compounds

to increase the quality of recycled polyolefins reaching levels of food packaging production - 3 newly developed tailored compounds

![]() to develop 5 market-ready products using bulk amounts (70-100%) of PLC-recycled materials

to develop 5 market-ready products using bulk amounts (70-100%) of PLC-recycled materials

![]() to prepare PLCtechnology replication&transfer starting with environmental decisions for two full-scale plants

to prepare PLCtechnology replication&transfer starting with environmental decisions for two full-scale plants

![]() to design, implement, test and validate the pilot PLC plant for efficient sorting of mixed hard plastic waste

to design, implement, test and validate the pilot PLC plant for efficient sorting of mixed hard plastic waste

![]() to implement standardized PLC-compatible procedures for mixed hard plastic waste pre-sorting in municipal waste treatment plants and thus to create standardized waste stream as an input to PLCplant (3,500t/y)

to implement standardized PLC-compatible procedures for mixed hard plastic waste pre-sorting in municipal waste treatment plants and thus to create standardized waste stream as an input to PLCplant (3,500t/y)

![]() to design, implement, test and validate the pilot unit for production of tailored compounds for products manufacturing with 70-90% recycled material from PLC (capacity 400t/y)

to design, implement, test and validate the pilot unit for production of tailored compounds for products manufacturing with 70-90% recycled material from PLC (capacity 400t/y)

![]() to design, implement, test and validate the innovative mobile 3Dprinting prototype with 100% recycled material from PLC (capacity 65t/y)

to design, implement, test and validate the innovative mobile 3Dprinting prototype with 100% recycled material from PLC (capacity 65t/y)

![]() to establish new circular business network (i.e. PLCnetwork) to boost cooperation between municipal waste treatment plants, plastic-recyclers and converters (12 plants, 3 countries)

to establish new circular business network (i.e. PLCnetwork) to boost cooperation between municipal waste treatment plants, plastic-recyclers and converters (12 plants, 3 countries)

![]() to increase the quality of recycled polyolefins reaching levels of food packaging production - 3 newly developed tailored compounds

to increase the quality of recycled polyolefins reaching levels of food packaging production - 3 newly developed tailored compounds

![]() to develop 5 market-ready products using bulk amounts (70-100%) of PLC-recycled materials

to develop 5 market-ready products using bulk amounts (70-100%) of PLC-recycled materials

![]() to prepare PLCtechnology replication&transfer starting with environmental decisions for two full-scale plants

to prepare PLCtechnology replication&transfer starting with environmental decisions for two full-scale plants

5355

3500

60

2800

Project aims to reach over 10K individuals with awareness raising actions i.e.:

Investeko S.A.

Wojska Polskiego 16G

41-600 Świętochłowice

tel: 32 258 55 80

fax: 32 707 45 33

biuro@investeko.pl

NIP: 634-281-00-82

REGON: 242953362

KRS: 0000420405