PLCtechnology is an innovative solution for deep cleaning and precise sorting of heterogenous hard plastic waste into recyclable fractions and the use of residual (non-recyclable) plastics for energy production with highly efficient gasification unit (“non-incineration”).

How does it work?

Węzeł 01

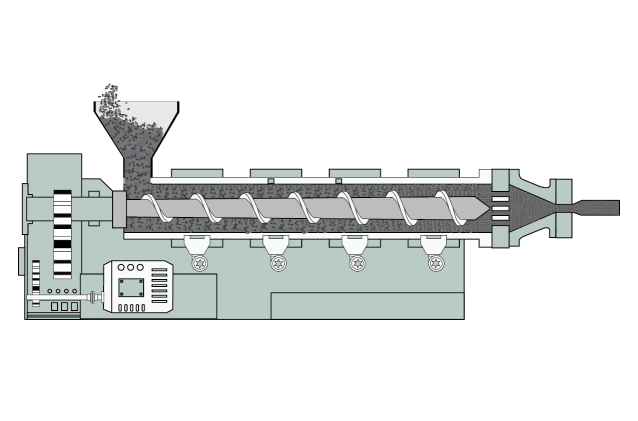

UNIT 1 — CLEANING

1 preparation of the waste input for cleaning; 2 Separation of reusable products; 3 deep cleaning and decrease of surface tension

Węzeł 01

UNIT 2 — SEPARATION

1 further cleaning; 2 precise separation of recyclable PP vs PE vs PS (directed to UNIT3); 3 separation of non-recyclable plastics (directed to UNIT4).

Węzeł 01

UNIT 3 — DRYING

Production of high-quality clean flakes rPP, rPE, rPS, with properties that suit plastic conversion partners needs and price that allow to compete with raw/virgin plastics

Węzeł 01

UNIT 4 — FUEL PREPARATION

Production alternative fuel for gasification purposes based on in-house non-recyclable residuals, biomass (external input) and possible other non-recyclable and high-calorific waste fractions.

An innovative modular system for compounding of custom-made polymer compounds containing high content (70-90%) of recycled material

PLC recyclates plus in-house postproduction waste (capacity: 400t/y). Due to relatively high batch-to-batch variations of the PLC recyclates, a smart quality process control will be implemented, which will be comprised of the input material quality inspection and adaptive control of the formulation of the material (innovation). Depending on the properties of the input material, the formulation will be automatically adapted in order to ensure decreased variability of the properties of end material.

Robotic 3D printing with recycled plastics is new material and technology combination that provides a lot of advantages in the process of recycling plastic and the development of new products of high quality.

TNR will upgrade its existing 3D printing system to enable systemic uptake of bulk amounts of PLC-based recyclates (capacity 65t/y which is +98% compared to existing 3D-printing technologies). The upgrades will include improvements in the monitoring system of the printing process in order to detect defects at an early stage, minimize failures and enable remote operation. Upgrades will include an automatic material feeder with integrated volumetric weighing and dehumidifier that will contribute to improved system capacity.

Investeko S.A.

Wojska Polskiego 16G

41-600 Świętochłowice

tel: 32 258 55 80

fax: 32 707 45 33

biuro@investeko.pl

NIP: 634-281-00-82

REGON: 242953362

KRS: 0000420405